Product Description

Structural Design:

Pure 3Y composition, offering flexibility for personalized staining and ceramic layering.

HT White combines high translucency with the benefits of an unshaded design, delivering approximately 41% translucency and a strength of 1400 MPa.

It is ideal for individualized staining and porcelain layering, making it suitable for restorations that require both aesthetic appearance and mechanical strength.

Its stable structure supports multi-unit cases and full-arch fixed restorations.

Indications:

Single posterior crowns, short-span anterior bridges, restorations requiring custom staining, full-arch designs

Key Features:

Unshaded design allows for flexible, personalized color application.

High translucency provides a natural appearance, while maintaining excellent strength.

Pure 3Y composition, offering flexibility for personalized staining and ceramic layering.

HT White combines high translucency with the benefits of an unshaded design, delivering approximately 41% translucency and a strength of 1400 MPa.

It is ideal for individualized staining and porcelain layering, making it suitable for restorations that require both aesthetic appearance and mechanical strength.

Its stable structure supports multi-unit cases and full-arch fixed restorations.

Indications:

Single posterior crowns, short-span anterior bridges, restorations requiring custom staining, full-arch designs

Key Features:

Unshaded design allows for flexible, personalized color application.

High translucency provides a natural appearance, while maintaining excellent strength.

Raw Material Distribution

Translucency: 41%

Sizes: 98mm × 12, 14, 16, 18, 20, 25, 30 mm (12mm and 30mm are made to order)

Strength: 1400 MPa

Shade: WHT

Sizes: 98mm × 12, 14, 16, 18, 20, 25, 30 mm (12mm and 30mm are made to order)

Strength: 1400 MPa

Shade: WHT

Indications

Full-arch

Sintering Curve

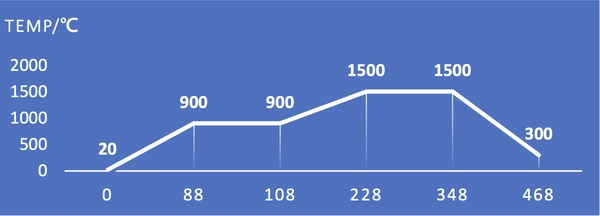

Within 3 units (8 hours)

- Heat at a rate of 10°C/min to 900°C, hold for 20 minutes.

- Then heat at 5°C/min to 1500°C, hold for 120 minutes.

- Cool down at 10°C/min to 300°C.

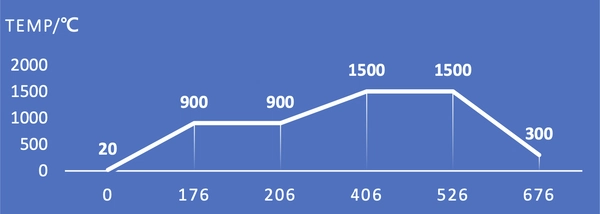

4–6 Unit Bridge (11.5 hours total)

- Heat at 5°C/min to 900°C, hold for 30 minutes

- Then heat at 3°C/min to 1500°C, hold for 120 minutes

- Cool down at 8°C/min to 300°C

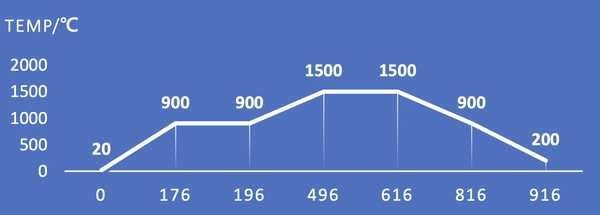

7+ Unit Bridge (16.4 hours total)

- Heat at 5°C/min to 900°C, hold for 20 minutes

- Then heat at 2°C/min to 1500°C, hold for 120 minutes

- Cool down at 3°C/min to 900°C

- Then cool down at 7°C/min to 200°C